Learn end milling basics types and best practices for beginners with Vast carbide tools for precision CNC machining and improved efficiency.

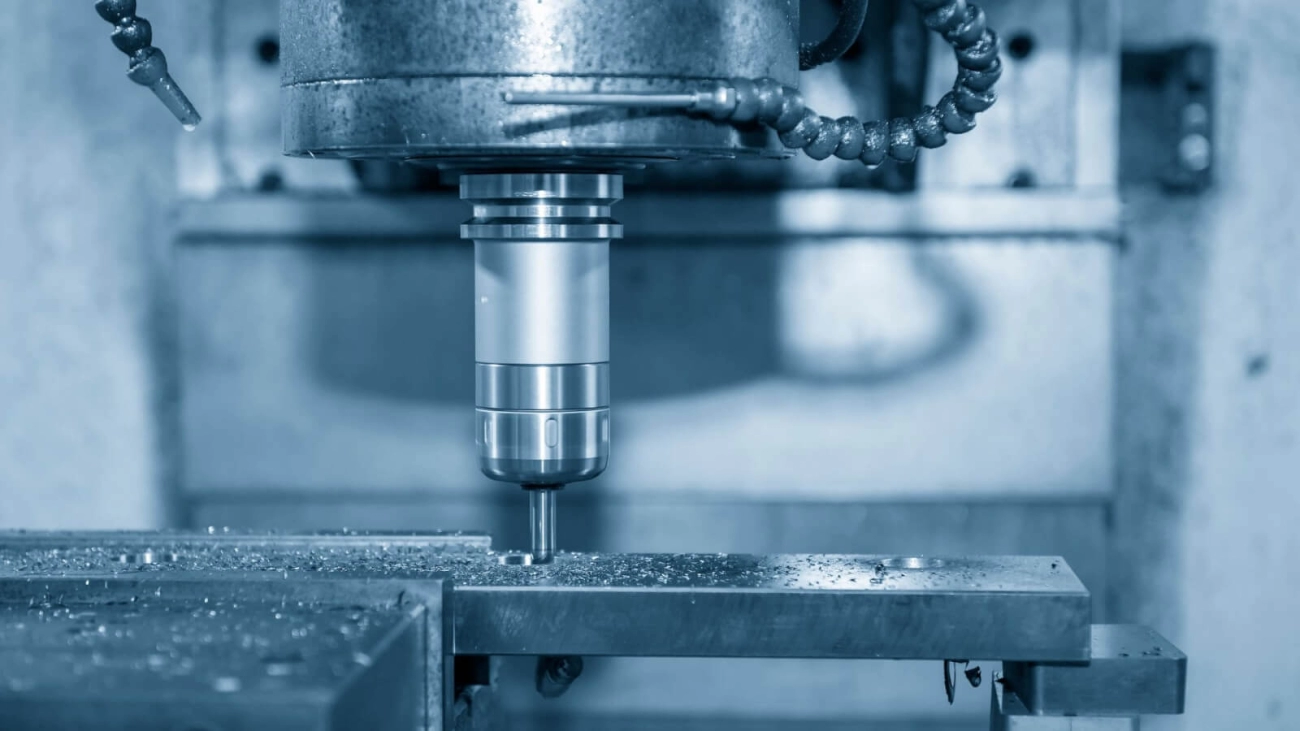

What Is End Milling Understanding the Process and Its Core Principles

End milling is a common machining process that uses a rotating cutter to remove material from a workpiece. Unlike other milling types, such as face milling which focuses on the surface, end milling cuts with the end of the tool, allowing precise holes, slots, and contours to be created.

How End Milling Works

- The end mill spins on its axis while moving along the workpiece.

- It cuts in different directions—axially (up and down) and radially (side to side).

- This versatility allows for complex shapes and profiles.

Differences From Other Milling Types

- End milling focuses on cutting with the bottom and sides of the tool.

- Face milling usually cuts only on the tool’s outer edge and is best for flat surfaces.

- Slot milling uses end mills but emphasizes narrow, deep cuts.

Key Components and Setup Basics

- The spindle holds the end mill and controls rotation speed.

- The workpiece is secured firmly, often in a vise or fixture.

- Proper speed and feed rates depend on material and tooling.

- Basic programming involves G-code commands to guide the tool path, including moves in X, Y, Z axes.

Historical Context and U.S Applications

End milling started gaining traction in the early 20th century as milling machines evolved for metal fabrication. In the U.S., industries like aerospace, automotive, and manufacturing quickly adopted end milling due to its precision and ability to handle tough alloys. Today, it’s a staple in both large-scale factories and small job shops across the country.

Understanding the core mechanics and differences of end milling sets a solid foundation for selecting the right tools and techniques for your projects. Ready to dive deeper into the types of end mills? Let’s explore what works best for your needs.

Types of End Mills Choosing the Right Tool for Your Project

End mills come in different shapes, sizes, and materials, so picking the right one matters a lot. The main categories are based on geometry and flute count:

- Square end mills have a flat cutting edge, perfect for sharp corners and slotting.

- Ball nose mills have a rounded tip, great for 3D contouring and curved surfaces.

- Roughing end mills feature serrated edges designed to remove large amounts of material quickly.

- Corner radius mills add strength and reduce chipping on edges.

Flute count usually ranges from 2 to 6:

- Fewer flutes (2-3) offer better chip evacuation and are great for softer materials like aluminum.

- More flutes (4-6) provide a smoother finish but need better chip control, ideal for harder metals.

Materials and Coatings Overview

- Carbide end mills are the go-to for most jobs in the US—they’re tough, wear-resistant, and handle higher speeds.

- High-speed steel (HSS) tools are less expensive but wear out faster.

- Coatings like TiN (Titanium Nitride) or TiAlN (Titanium Aluminum Nitride) improve heat resistance and prolong tool life.

Selection Matrix with Vast Product Examples

Vast offers a wide range of end mills tailored to your project needs:

| End Mill Type | Best For | Material | Flutes | Coating |

|——————–|————————|————|——–|—————-|

| Square End Mill | Slotting, Profiling | Carbide | 2-4 | TiAlN |

| Ball Nose Mill | 3D Contouring, Mold Making | Carbide | 4 | TiCN |

| Roughing End Mill | Rapid Material Removal | Carbide | 3-4 | Uncoated/TiN |

Pro Tips on Helix Angles and Chatter Avoidance

- Helix angle (the curve of the flutes) matters. Low angles (around 30°) work well for tough materials, pushing chips out slowly. Higher angles (40°+) help with chip evacuation and surface finish in softer metals like aluminum.

- To reduce chatter (vibrations that damage surface finish), choose the right flute count, slow down feeds, and use end mills with the proper helix angle for your material.

Choosing the right end mill upfront saves time, cuts costs, and boosts your milling efficiency whether you’re working in a US machine shop or your local home workshop.

Step-by-Step End Milling Setup and Operation for Beginners

Getting started with end milling doesn’t have to be overwhelming. Here’s a simple guide to help you set up and run your milling operation smoothly.

Securing the Workpiece

First, make sure your workpiece is firmly clamped or held in place. Use a vise or clamps on your milling table to prevent any movement. A steady workpiece improves precision and tool life.

Choosing Speed and Feed Rates

Selecting the right speed (RPM) and feed rate is key. Here’s what to keep in mind:

- Material matters: Softer materials like aluminum can handle higher speeds. Harder metals like steel need slower speeds but higher feed pressure.

- Tool specifics: Match your feed and speed settings to the type of end mill and its diameter. Carbide end mills often allow faster speeds than HSS tools.

- When in doubt, check the manufacturer’s guidelines to avoid tool wear or breakage.

Basic G-code Programming for Milling Paths

Most end milling jobs use CNC machines that follow G-code commands. For beginners:

- Start simple: Focus on basic linear moves (G01) and rapid moves (G00).

- Define depths carefully: Set your cutting depth per pass; avoid removing too much material at once.

- Use canned cycles for pocketing or contouring to save programming time.

Conventional versus Climb Milling and Depth Rules

Understanding these milling styles helps optimize your setup:

- Conventional milling feeds the tool against the rotation. It’s easier on older machines but may cause more tool wear.

- Climb milling feeds the tool with the rotation, offering better finishes and tool life if your machine is rigid enough.

- Always start cutting with shallow depths (around 1/3 of the tool diameter) and increase gradually as you get comfortable.

Safety and Chip Evacuation Techniques

Safety can’t be overlooked:

- Always wear eye protection and avoid loose clothing around the milling machine.

- Use a chip guard or enclosure if possible.

- Efficient chip evacuation keeps your cutting area clear and prevents tool damage — options include air blasts, coolant, or a chip conveyor.

- Clean the workspace regularly to avoid slips or jams.

By following these steps, you’ll set up your end milling projects with confidence and efficiency, whether you’re working in a local machine shop or your home workshop here in the US.

End Milling Best Practices Tips to Maximize Efficiency and Tool Life

Getting the most out of your end mills means dialing in the right feed rates and cutting depths. Too fast or too deep can wear your tool quickly, while too slow wastes time and can cause rubbing. Here are some tips to keep your end milling efficient and your tools lasting longer.

Optimizing Feed Rates and Depths

- Follow manufacturer guidelines for feed and speed — Vast carbide end mills often come with recommended settings.

- Adjust feed rates based on material — softer metals like aluminum allow higher feeds, while harder steels need slower, steady cuts.

- Start with conservative depths of cut — usually between 0.5 to 1 times the tool diameter, then adjust based on finish and tool wear.

- Avoid aggressive axial depths for standard end mills to prevent tool breakage and chatter.

Common Pitfalls and Troubleshooting

- Chatter — caused by improper feed, speed, or too long unsupported tool length. Reduce speed or increase feed to counter.

- Excessive tool wear — often due to too high feed rates or insufficient chip evacuation. Use coated end mills and ensure proper coolant or air blast.

- Poor surface finish — can result from worn tools, dull edges, or wrong helix angle. Check tool condition and consider switching helix angles for better chip flow.

Material-Specific Advice for Aluminum and Steel

- Aluminum: Use sharp, polished tools with 2-3 flutes to avoid chip packing. Higher spindle speeds and feed rates work well here. Good chip evacuation is critical — air blasts or mist coolant help.

- Steel: Slower feed rates, lower RPM, and using roughing end mills or trochoidal milling helps keep tool heat down and extend life. Carbide tools with TiAlN coatings show great wear resistance in steel.

Advanced Techniques Like Trochoidal Milling

Trochoidal milling is a great way to maintain consistent tool engagement. It uses circular cutting motions to reduce heat buildup and tool wear, especially useful with harder steels or deeper cuts. This technique:

- Reduces cutting forces

- Improves chip evacuation

- Allows faster feed rates without sacrificing tool life

Applying these best practices helps your end milling jobs run smoother, lowers costs, and improves part quality, especially for US shops juggling various materials and production scales.

Applications of End Milling Real World Uses in Manufacturing and DIY

End milling plays a big role across many industries here in the US. It’s a go-to technique in automotive and aerospace manufacturing for creating precise parts and complex shapes. You’ll see it used to machine engine components, structural parts, and custom aerospace fittings where accuracy matters most. Woodworking shops also rely on end milling for cutting profiles and grooves, shaping furniture parts, and crafting custom designs.

For the home shop or DIY enthusiast, end milling tools open up new possibilities—making custom brackets, engraving, or cutting parts for hobby projects becomes much easier and more accurate. Whether you’re working with aluminum, steel, or wood, the right end mill makes all the difference.

One great example is how Vast end mills have helped US manufacturers improve their production lines. Companies report smoother cuts, longer tool life, and faster machining times using Vast carbide end mills, especially when working with tough materials. That efficiency boost can mean meeting deadlines faster and cutting costs, which is a win in any shop.

No matter your project size or industry, end milling offers a versatile, reliable solution built for precision and performance.

Why Choose Vast for Your End Milling Needs

When it comes to end milling, Vast stands out as a trusted brand in the U.S. market. We offer affordable, high-precision carbide end mills designed to deliver consistent results whether you’re machining aluminum, steel, or other materials. Our tools are engineered with top-quality coatings and optimized helix angles to reduce chatter and extend tool life, helping you get the job done faster and cleaner.

Vast focuses on supplying a wide range of end mills—from roughing end mills to ball nose and precision contouring tools—perfectly suited for both CNC end milling and manual setups. Plus, our products are backed by reliable customer support and fast shipping right here in the USA.

Ready to elevate your milling projects? Check out the full selection of Vast carbide end mills and start milling with confidence today.