Discover affordable precision CNC machining services in China with fast turnaround advanced 5-axis milling and tight tolerances for prototypes and production.

What is CNC Machining A Quick Primer for First Timers Core Definition and Key Processes

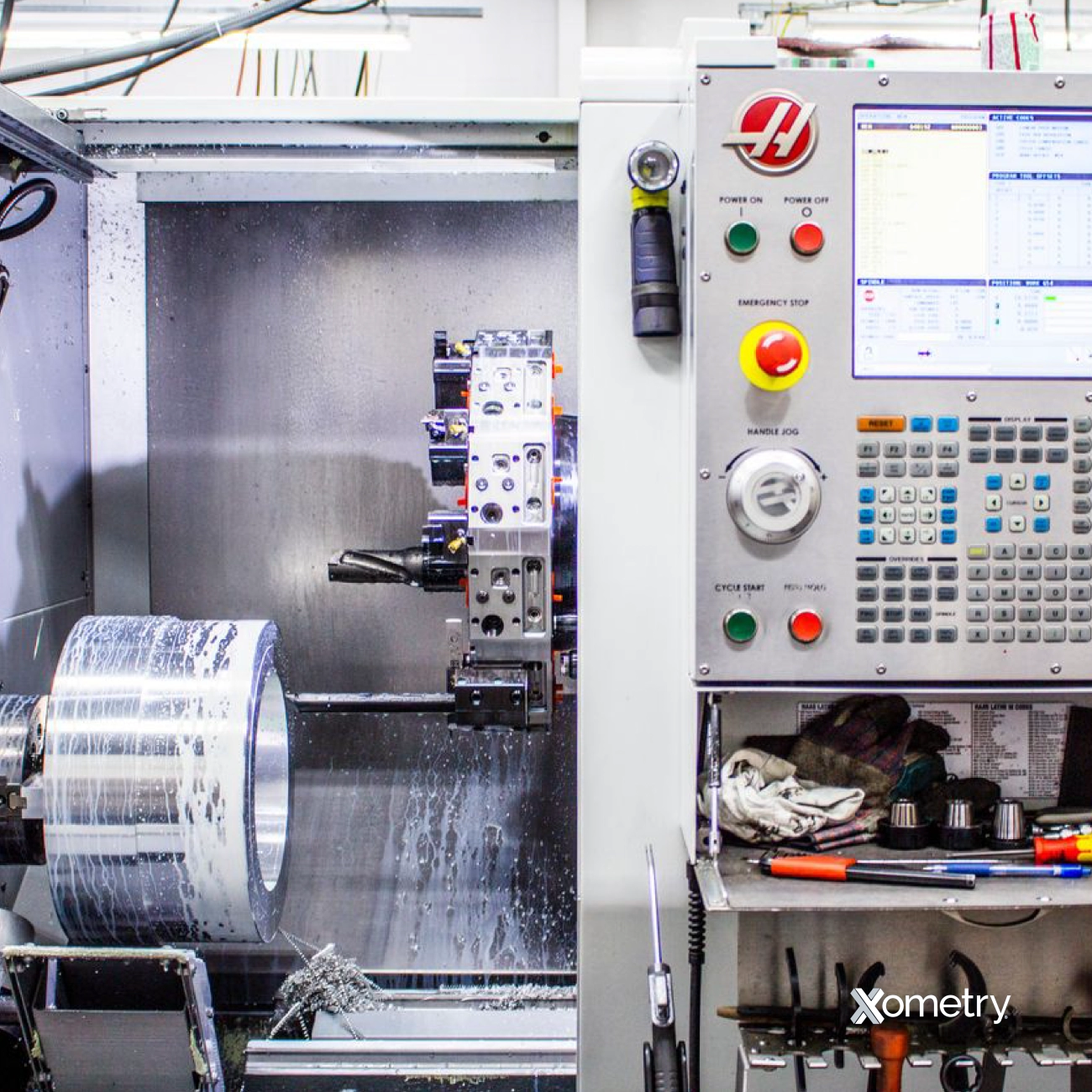

CNC machining stands for Computer Numerical Control machining. It’s a manufacturing process where computerized systems control machine tools like mills, lathes, and routers to create precise parts from metal, plastic, or other materials. This method uses programmed instructions to guide cutting tools, enabling high accuracy and repeatability.

Key processes in CNC machining include:

- Milling: Removing material by rotating cutting tools to shape a workpiece, often used for complex surfaces.

- Turning: Spinning the workpiece on a lathe to produce cylindrical shapes.

- Drilling: Creating holes with precise depth and diameter.

- Grinding and Cutting: Refining surfaces and edges to tight tolerances.

The result is precision parts made with consistent quality, often impossible to achieve manually. For those new to manufacturing or product development, understanding CNC machining is essential because it underpins the creation of everything from prototypes to final products. It also supports various industries due to its versatility and precision.

What is CNC Machining A Quick Primer for First Timers Benefits Overview and Vast Tie In

CNC machining offers some clear benefits that make it a go-to choice for many businesses. First off, it delivers high precision and consistency, meaning parts come out almost exactly as designed every time. This is crucial for industries where tight tolerances matter, like aerospace or medical devices.

Another big plus is speed. CNC machines can handle complex tasks fast, helping companies move from prototype to production quickly. Plus, it’s flexible—you can run low volume CNC production or scale up easily without sacrificing quality.

When working with Vast, you get all these benefits plus a partner who knows the China CNC machining services landscape inside out. Vast’s expertise in precision CNC milling China and custom CNC turning services means you get parts that fit your exact specs without extra hassle. Their ISO certified machining factories and rapid prototyping manufacturers in Shenzhen and Dongguan further speed up product development and delivery.

In short, CNC machining saves time, cuts costs, and improves quality—especially when teamed with a reliable provider like Vast.

The Strategic Advantages of Choosing CNC Machining Services in China Cost Efficiency and Technological Edge

When it comes to CNC machining services China offers a strong combination of cost savings and advanced technology. The lower labor and production costs mean you get precision CNC milling and custom CNC turning services at competitive prices without sacrificing quality.

China’s manufacturing hubs like Shenzhen and Dongguan have invested heavily in the latest equipment, including 5-axis CNC machining centers that deliver tight tolerances and complex geometries. This tech edge lets you access high precision EDM wire cutting and aluminum CNC prototypes automotive parts that meet strict standards.

Plus, many ISO certified machining factories in China follow global quality controls, so you don’t have to worry about inconsistent output. The mix of affordability and cutting-edge processes gives U.S. buyers a strategic advantage for product development, rapid prototyping, and even low volume CNC production runs.

In short, partnering with China-based CNC machining services means you get advanced machining capabilities paired with cost-effective pricing that supports your bottom line.

The Strategic Advantages of Choosing CNC Machining Services in China Speed Scalability and Ecosystem Perks

When you partner with CNC machining services in China, one of the biggest advantages is how fast and scalable the process can be. China has massive manufacturing hubs like Shenzhen and Dongguan that specialize in rapid prototyping manufacturers and low volume CNC production. This means whether you need a one-off custom CNC turning service or a large batch of precision CNC milling parts, you can get quick turnarounds without sacrificing quality.

The ecosystem around CNC machining in China is also a big plus. From ISO certified machining factories offering 5-axis CNC machining tolerances to suppliers providing CNC parts anodizing finishes, everything is tightly integrated. This not only speeds up your project but reduces the hassle of managing multiple vendors.

Plus, the access to advanced tech like high precision EDM wire cutting tools means your parts meet tight tolerances while still coming in on time. With solid logistics networks and experience handling overseas shipments, China makes scaling your production smooth whether you’re launching new aluminum CNC prototypes for automotive or expanding consumer electronics lines.

In short, choosing CNC machining services in China means you get speed, flexibility, and a supportive manufacturing ecosystem that helps bring your product ideas to market faster.

Top Industries Thriving with China CNC Machining Expertise Aerospace Defense and Automotive EV

When it comes to CNC machining services in China, some industries stand out for their heavy reliance on precision and advanced manufacturing. Aerospace, defense, and automotive EV sectors are major beneficiaries of China’s CNC capabilities.

Aerospace and Defense

These industries demand extremely tight tolerances and complex parts, including components made using high precision EDM wire cutting and 5-axis CNC machining tolerances. China’s ISO certified machining factories offer the quality and consistency required to meet strict safety and performance standards. From lightweight aluminum CNC prototypes to custom CNC turning services of critical parts, China delivers reliable solutions for these high-stakes applications.

Automotive and Electric Vehicles (EV)

China has grown into a hub for rapid prototyping manufacturers and low volume CNC production, especially in regions like Shenzhen and Dongguan. The automotive industry, particularly the fast-changing EV market, needs quick turnarounds on parts like anodized CNC parts and precision milled components. With competitive pricing and scalable production, CNC machining services in China allow U.S. companies to access advanced manufacturing without sacrificing speed or quality.

These sectors thrive on China’s blend of cost efficiency and technical expertise, making CNC machining services here a strategic choice for complex, high-value projects.

Top Industries Thriving with China CNC Machining Expertise Medical Devices Consumer Electronics and Trends

China’s CNC machining services have become a go-to for industries like medical devices and consumer electronics, thanks to their precision and advanced tech. In medical device manufacturing, high-precision CNC milling and custom CNC turning services ensure parts meet strict regulatory standards. This is crucial for components like surgical tools, implants, and diagnostic equipment where accuracy and reliability are non-negotiable. Many ISO certified machining factories in China specialize in this sector, offering capabilities like 5-axis CNC machining tolerances and high precision EDM wire cutting.

The consumer electronics industry benefits from rapid prototyping manufacturers in Shenzhen and low volume CNC production hubs in Dongguan. These centers excel at producing prototype aluminum CNC parts and small batches with fast turnaround times. Whether it’s housing for smartphones, wearable tech, or other gadgets, surface finishes like CNC parts anodizing finishes add both durability and style.

Current trends point to increased demand for smarter, lighter, and more complex components made possible by China’s CNC machining ecosystem. For U.S. buyers, this means access to cost-effective, high-quality parts that keep up with fast-moving markets.

How to Select the Right CNC Machining Partner in China A Buyers Checklist Evaluate capabilities and quality assurance

Picking a reliable CNC machining partner in China starts with checking their technical skills and quality controls. Here’s what you should focus on:

- Manufacturing capabilities: Make sure they offer the specific services you need, like precision CNC milling, custom CNC turning services, or 5-axis CNC machining tolerances. If you require rapid prototyping or low volume CNC production, confirm they have experience in those areas.

- Equipment and technology: Look for factories with up-to-date machines and ISO certified machining factories. Advanced tech like high precision EDM wire cutting or CNC parts anodizing finishes signals strong quality potential.

- Quality assurance systems: Check if they follow strict quality control procedures and use tools like Statistical Process Control (SPC) or in-house inspection labs. Ask to see past quality reports or certifications.

- Samples and prototypes: Request aluminum CNC prototypes or other test parts to evaluate their accuracy and finish before committing to large orders.

- Compliance and standards: Ensure they meet international standards relevant to your industry, especially if you’re in aerospace, automotive EV, or medical devices, where tolerances and certifications are critical.

By thoroughly vetting these areas, you can find a China CNC machining services provider who consistently delivers precise, reliable parts tailored for the US market.

How to Select the Right CNC Machining Partner in China A Buyers Checklist Communication reliability and pricing transparency

When you’re outsourcing CNC machining services in China, clear communication and honest pricing are must-haves. Without them, delays and unexpected costs can kill your project before it even starts. Here’s what to watch for:

Communication reliability

- Choose partners who respond quickly and clearly. A good supplier will keep you updated on every step, from quoting to delivery.

- Make sure they understand your project details—ask for proof like photos or progress updates.

- Language shouldn’t be a barrier. Look for a team comfortable with English to avoid misunderstandings.

Pricing transparency

- Get a detailed breakdown of costs: material, machining, finishing, shipping, and any extra fees. Avoid vague quotes.

- Watch out for hidden charges or last-minute price hikes. A trustworthy partner provides consistent pricing from start to finish.

- Request an instant CNC quote if possible. This helps you compare suppliers fairly and saves time.

By prioritizing clear communication and upfront pricing, you minimize risks and build a smoother partnership for your CNC projects in China.

How to Select the Right CNC Machining Partner in China A Buyers Checklist Red flags to Avoid and Actionable Tools

Choosing the right CNC machining services China partner can make or break your project. Here are some red flags to watch out for and tools you can use to avoid costly mistakes.

Red flags to avoid

- Lack of certifications: If a factory doesn’t show ISO certification or quality management proof, be cautious.

- Poor communication: Slow or unclear responses often signal deeper issues.

- No samples or references: Reliable partners will offer prototypes or show past work.

- Unrealistically low prices: If it sounds too good to be true, it probably is.

- Hidden fees or vague quotes: Quotes should be clear and detailed upfront.

- No quality assurance plan: Avoid shops that don’t have clear inspection or testing processes.

- Unwillingness to sign NDAs or contracts: Your IP protection matters, so that’s a must.

Actionable tools to vet CNC machining partners

- Request instant China CNC quote tools online for quick pricing comparisons.

- Use third-party inspection services to verify quality on-site before shipping.

- Leverage platforms with reviews like Alibaba, Made-in-China, or specialized industry forums.

- Ask for detailed material certifications and machining reports with your order.

- Start with low volume CNC production orders to test responsiveness and quality.

- Get a non-disclosure agreement signed upfront to protect your designs.

By being aware of these red flags and using these tools, you can confidently choose a CNC machining partner in China that meets your standards—saving time, money, and headaches.

Spotlight on Vast Elevating CNC Machining Standards in China Brand Story Unique Value Props and Success Metrics

Vast has built a strong reputation in the CNC machining services China market by focusing on precision, reliability, and customer-first solutions. Starting as a small shop, Vast invested heavily in cutting-edge equipment like 5-axis CNC machining and high precision EDM wire cutting to meet tough US standards. Their journey is rooted in delivering fast, custom CNC turning services and precision CNC milling China clients demand.

What sets Vast apart is their commitment to quality combined with flexibility. They offer rapid prototyping manufacturers in Shenzhen-level speed while also handling low volume CNC production in Dongguan with ease. Vast pairs ISO certified machining factories with detailed CNC parts anodizing finishes to ensure every part is flawless.

Success here isn’t just about output volume; Vast tracks key metrics like on-time delivery rate, first-pass yield, and customer satisfaction scores. These numbers consistently show Vast outperforms many competitors, especially for aluminum CNC prototypes automotive and medical device parts. Their process guarantees parts with tight 5-axis CNC machining tolerances that meet industry specs without costly delays.

In short, Vast isn’t just another China supplier. They raise the bar on CNC machining standards China-wide by blending technology, quality control, and a deep understanding of US buyer needs into every project.

Spotlight on Vast Elevating CNC Machining Standards in China Client Testimonials and Visuals

At Vast, we don’t just talk about quality—we prove it through the voices of our clients and clear results. Many U.S.-based companies, from automotive to consumer electronics, have praised Vast for delivering precision CNC milling China projects on time with exact tolerances. One client said, “Vast’s custom CNC turning services helped us cut our prototype lead time in half without sacrificing quality.” Another noted the smooth communication and fast turnaround, essential for rapid prototyping manufacturers in Shenzhen.

Our portfolio shows a wide range of successful projects, including aluminum CNC prototypes for automotive parts and high-precision EDM wire cutting components. These visuals highlight not just the parts but the fine anodizing finishes and surface quality that meet strict industry standards.

These testimonials and proof points reflect our commitment to raising the bar on what you can expect from CNC machining services in China—bringing U.S. customers closer to flawless parts, transparent processes, and dependable delivery every time.

Step by Step Guide From Quote to Delivery with Vast CNC Services Upload CAD Files and DFM Review

Working with Vast CNC machining services in China starts simple. First, you upload your CAD files to their platform or send them directly. This is where the process kicks off.

After you share your design, Vast’s engineers perform a Design for Manufacturability (DFM) review. This step checks your files for any potential issues that could slow down production or increase costs. They’ll suggest tweaks to improve machining efficiency while keeping your specs intact.

By catching problems early, Vast helps avoid delays and ensures your project stays on budget. This review is critical, especially when dealing with precision CNC milling in China or custom CNC turning services, where tight tolerances matter.

In short, upload your CAD, get the DFM feedback, then move forward confidently knowing your parts are optimized for smooth production.

Step by Step Guide From Quote to Delivery with Vast CNC Services Material finish selection production QC and shipping

Once your CAD files are uploaded and Design for Manufacturability (DFM) reviews are done, the next step is picking the right material and finish for your parts. Vast offers a wide range of options—from aluminum CNC prototypes with anodizing finishes to other metals suited for high precision applications. This flexibility ensures your parts meet both functional needs and aesthetic standards.

During production, Vast strictly follows quality control (QC) procedures. Each batch undergoes detailed inspections to meet ISO certified machining factory standards. This means you can trust the precision CNC milling China experts at Vast to deliver parts within tight tolerances, including complex 5-axis CNC machining jobs or custom CNC turning services.

Once your parts pass QC, Vast coordinates reliable shipping with clear timelines and tracking. Whether you’re ordering low volume CNC production from Dongguan or rapid prototyping manufacturers in Shenzhen, the shipping process is optimized for speed and care. This step-by-step flow reduces errors and keeps you informed from start to finish, so you get your parts when you need them without surprises.

Common Challenges and Smart Solutions in Outsourcing to China IP Protection and Cultural Language Gaps

Outsourcing CNC machining services to China comes with some common hurdles, especially around IP protection and cultural language gaps. Protecting your intellectual property is often a top concern for U.S. companies. To address this, choose ISO certified machining factories that follow strict confidentiality agreements and have strong IP policies in place. Signing non-disclosure agreements (NDAs) before sharing designs is a must.

Language and cultural differences can also cause miscommunication or delays. Here’s how to handle it:

- Clear Communication: Work with partners who provide English-speaking project managers or technical staff to bridge the language gap.

- Documentation: Always get detailed written specifications and confirmations to minimize misunderstandings.

- Frequent Updates: Regular check-ins and progress reports help catch issues early.

- Local Visits: When possible, visiting the factory or using trusted third-party inspection services can improve trust and clarity.

By planning ahead and choosing the right partner, you can overcome these challenges and confidently outsource your machining projects to China.

Common Challenges and Smart Solutions in Outsourcing to China Supply Chain Disruptions and Future Proofing

Outsourcing CNC machining services to China comes with its share of supply chain uncertainties. Delays from raw material shortages, customs hold-ups, or transport slowdowns can disrupt project timelines, especially in industries like automotive or aerospace where timing is crucial.

To future-proof your supply chain when working with China CNC machining providers, consider these smart steps:

- Diversify Suppliers: Don’t rely on a single factory or region. Spread your orders across a few trusted partners in different provinces to reduce risks tied to local disruptions.

- Plan for Lead Times: Build buffer time into your schedules to handle unexpected delays without derailing your project.

- Use Local Warehousing: Keep inventory closer to US customers through warehouses or fulfillment centers to minimize shipping risks.

- Stay Updated on Trade Policies: Monitor tariffs, customs changes, and geopolitical shifts that could impact shipping or costs.

- Leverage Tech for Transparency: Work with providers offering real-time production tracking and instant CNC quotes to quickly spot and resolve issues.

- Invest in Strong Communication: Regular status checks and clear escalation paths help catch problems early.

By proactively managing these challenges, you can tap into the cost efficiency and precision of CNC machining in China while keeping your supply chain resilient and reliable for the US market.