Discover how helix angle affects machining efficiency and tool performance with expert tips on end mills gears and optimal selections.

What Is a Helix Angle The Fundamentals Explained

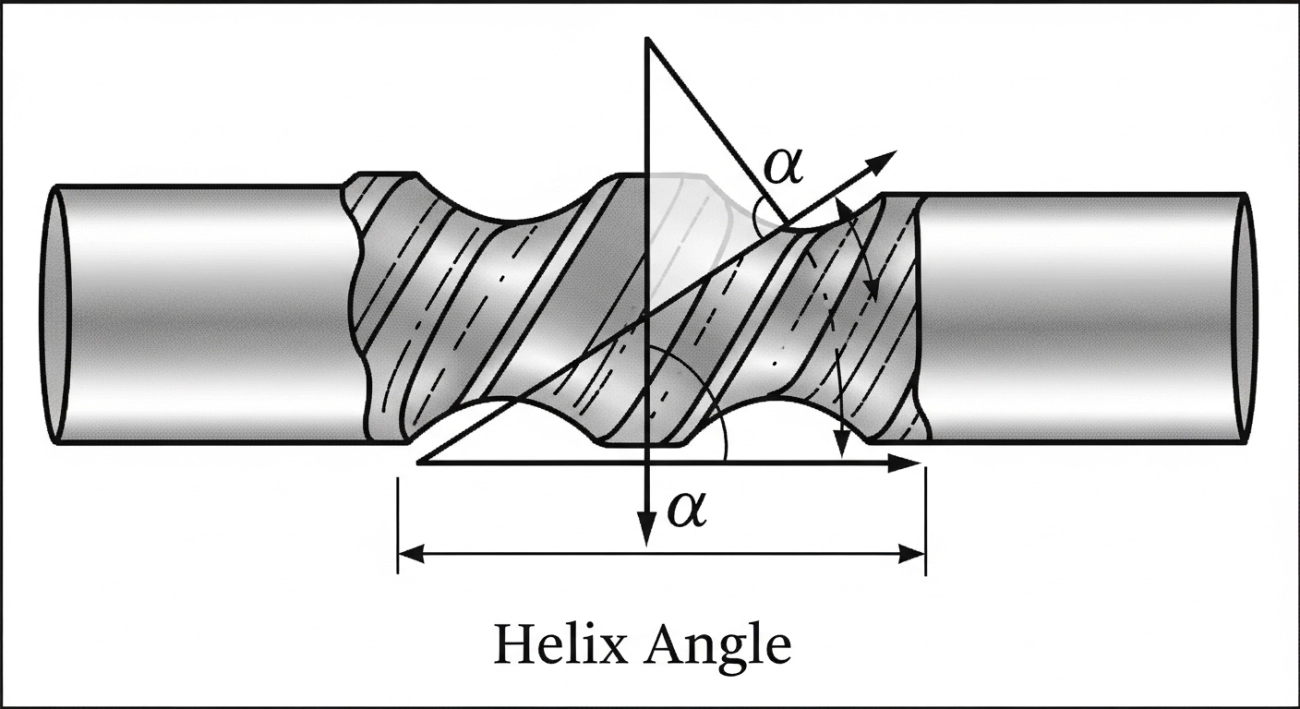

Ever wondered what a helix angle really means and why it matters? At its core, the helix angle is the angle formed between the edge of a spiral feature—like the threads on a screw, the teeth of a helical gear, or the cutting edges on tools like end mills—and the axis of the tool or part.

Core Definition and Geometry

The helix angle shows how tightly or loosely the spiral wraps around the axis. Imagine wrapping a ribbon around a cylinder; the angle the ribbon makes with the cylinder’s length is the helix angle. A higher helix angle means a steeper spiral, while a lower helix angle means a more gradual, shallower wrap.

| Term | Description |

|---|---|

| Helix Angle | Angle between the spiral edge and the tool or shaft’s central axis |

| Lead | Linear distance along the axis corresponding to one complete spiral turn |

| Pitch | Distance between corresponding points on adjacent spirals |

Key Parameters Influencing Helix Angle

Several factors impact the helix angle in different applications:

- Lead and pitch: These geometrical factors influence spiral tightness and spacing.

- Tool diameter: Larger tools can often accommodate different helix angles.

- Material being cut or transmitted: Softer metals may benefit from high helix angles for better chip flow.

- Purpose of the tool or gear: For example, chip evacuation needs or smooth power transmission.

Common Misconceptions

- Helix angle equals lead angle: They are related but not the same; lead angle depends on helix angle and pitch diameter.

- Higher helix always better: Actually, higher helix angles improve chip flow but can weaken tool strength.

- Helix angle only matters for cutting tools: It’s also critical in gear design, thread manufacturing, and even wind turbines.

Understanding the helix angle’s basics helps you choose or optimize tools and parts for better results, whether machining aluminum or designing efficient helical gears.

Helix Angles in Action Applications Across Industries

Helix angles play a crucial role in many industries, shaping how tools and machines perform. In machining, you often see helix angles in end mills, drills, and taps. For example, helical end mill cutters use specific helix angles to control cutting forces and improve chip evacuation machining, which results in cleaner cuts and longer tool life. High helix tools with steep angles are favored for softer materials like aluminum, while lower helix angles work better with harder metals.

In mechanical power transmission, helix angles are a fundamental part of helical gear design. The angle determines how smoothly gears mesh, affecting noise levels, load capacity, and overall efficiency. A well-chosen thread helix angle ensures strong, reliable gear contact without excessive wear.

Beyond traditional uses, helix angles are becoming essential in emerging fields like wind turbines. The blades rely on optimized helix angles to capture wind energy efficiently and reduce stress during operation. This shows how versatile the concept is, influencing everything from heavy machinery to renewable energy solutions.

From improving tool performance in machining to powering industries with gears and turbines, helix angles make a big difference in practical applications across the board.

The Impact of Helix Angle on Performance Pros Cons and Optimization

The helix angle plays a big role in how tools and gears perform. When it comes to cutting, a higher helix angle generally reduces cutting forces. This means less stress on your tool and your machine, which can boost tool life and reduce heat buildup. That’s a win for tough jobs or working with metals like aluminum, where a smoother cut and better chip flow matter.

On the flip side, a high helix angle can sometimes cause chatter (vibrations) in less rigid setups. Lower helix angles offer stronger cutting edges and are better for harder materials or heavy cuts but don’t evacuate chips as quickly. This impacts surface finish—higher angles give a smoother finish by gently slicing the material, while lower angles might leave more marks, especially on softer metals or plastics.

Chip evacuation is critical, especially in milling and drilling. Tools like helical end mills with higher helix angles keep chips moving away from the cutting zone, preventing jams and heat buildup. That means less downtime and cleaner cuts.

Material specific tips:

- Aluminum and softer metals: Use higher helix angles (around 35 to 45 degrees) for smoother cuts and better chip flow.

- Hard metals and steels: Lower helix angles (20 to 30 degrees) offer better tool edge strength and reduce the risk of tool wear.

- Composite materials: Variable helix tools help reduce vibration and improve finish.

Balancing these factors helps optimize tool performance and durability. Tailoring the helix angle to your material and machine setup is key for the best results.

How to Calculate and Measure Helix Angles Like a Pro

Knowing the helix angle of a tool or gear is vital for getting the best performance out of your machining or mechanical setup. Here’s a simple way to calculate and measure helix angles without getting bogged down in complicated formulas.

Step by Step Calculation Guide

- Understand the basics: The helix angle is the angle between the edge of the tool or gear tooth and the axis of the shaft or tool.

- Gather measurements: You’ll need the lead (the distance the tool or thread moves along the axis in one full turn) and the diameter of the tool or gear where the angle is measured.

- Use this formula:

[

text{Helix Angle} = arctanleft(frac{text{Lead}}{pi times text{Diameter}}right)

]

This formula helps calculate the angle in degrees. - Calculate the arctan using a calculator or a smartphone app. This will give you the helix angle directly.

This method works for tools like helical end mills, thread helix angle on taps, and helical gear design.

Measurement Techniques

- Protractor Method: If you have the tool at hand, use a digital protractor or angle gauge to measure the angle directly from the edge relative to the tool’s axis.

- Optical Comparator: In a machine shop, this device projects the tool profile onto a screen where exact angles can be measured with high precision.

- 3D Scanning and Software: For complex tools, scanning their geometry allows software to calculate the helix angle digitally.

- Microscopic Inspection: For small tools, microscopes with built-in measuring software can also help identify the helix angle.

By combining simple calculations with these measurement techniques, you can ensure your helix angles are spot on, improving chip evacuation machining and overall tool performance.

Choosing the Right Helix Angle Expert Tips from Vast Experience

Picking the right helix angle can make a big difference in your machining or gear setup. Here’s what I keep in mind when choosing:

Factors to Consider

- Material TypeSoft metals like aluminum usually benefit from a high helix angle (30° or more) because it helps with smooth chip evacuation. Harder materials might do better with a lower helix angle to reduce tool wear.

- Cutting SpeedHigher speeds generally work well with higher helix angles, which ease cutting forces and improve surface finish.

- Machine RigidityLess rigid machines may require a lower or moderate helix angle to prevent tool chatter and vibrations during cutting.

When to Go Variable or Custom Helix Angles

- Variable Helix End MillsThese tools change the helix angle along the flute, reducing harmonics and vibration. If you’re struggling with chatter on CNC mills, a variable helix can be a game changer.

- Custom Helix AnglesCustom angles might be necessary for specialized jobs, like unique thread helix angles or specific gear designs, offering better performance than off-the-shelf options.

Troubleshooting Common Issues

- Poor Chip EvacuationIf chips jam, consider moving to a higher helix angle or adjusting your tool rake angle for better chip flow.

- Excessive Tool Wear or HeatLowering the helix angle can reduce cutting forces and heat, extending tool life, especially in tough materials.

- Surface Finish ProblemsA higher helix angle usually improves finish as it produces smoother cutting action. If finish looks rough, trying a tool with a higher helix can help.

Choosing the right helix angle takes a bit of experimentation, but focusing on material, speed, and machine setup will guide you toward the best results.