Discover expert vacuum casting factory services for precise prototypes and low-volume production with fast turnaround and high-quality finishes.

Introduction to Vacuum Casting

Vacuum casting is a manufacturing process that uses a vacuum to draw liquid polyurethane or other resin into silicone molds. This technology is highly effective for creating detailed, high-quality prototypes and low-volume production parts. Unlike traditional molding methods, vacuum casting reduces air bubbles and defects, resulting in superior surface finish and dimensional accuracy.

Vacuum casting plays a crucial role in prototype development and short production runs because it offers a cost-effective, fast turnaround solution without the need for expensive tooling. It allows designers and engineers to test form, fit, and function with reliable parts before committing to large-scale manufacturing.

Key industries benefiting from vacuum casting include automotive, consumer electronics, aerospace, medical devices, and defense. Each of these sectors relies on vacuum casting for rapid prototyping, functional testing, and custom part production that meets precise specifications.

What is a Vacuum Casting Factory

A vacuum casting factory is a specialized facility that focuses on producing parts using vacuum casting technology. Its main function is to create accurate, high-quality prototypes and low-volume production runs by forming parts with polyurethane or other casting materials under a vacuum.

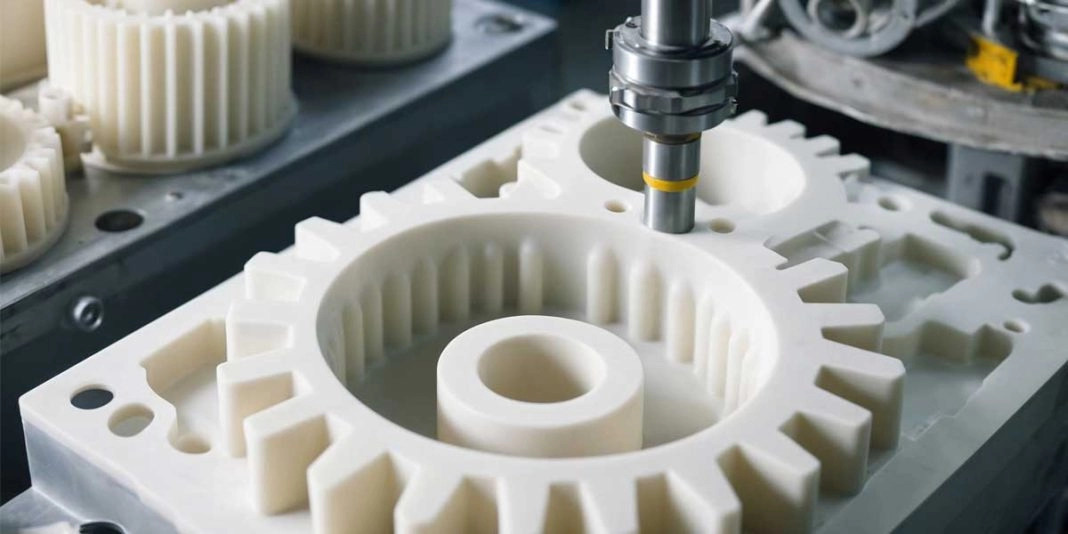

These factories are equipped with key tools like silicone mold making stations, vacuum chambers for resin casting, and finishing areas for sanding, painting, or assembly. The setup usually includes master pattern fabrication zones, molding rooms, and quality control labs to ensure precision.

Typical services you’ll find at a vacuum casting factory include:

- Silicone mold preparation

- Polyurethane casting using vacuum degassing to prevent bubbles

- Post-processing like trimming, polishing, and painting

- Custom finishes and assembly for ready-to-use prototypes or parts

This setup makes vacuum casting factories ideal for businesses needing quick turnaround on functional parts without the cost of tooling for traditional manufacturing methods.

How Vacuum Casting Works Step-by-Step Process

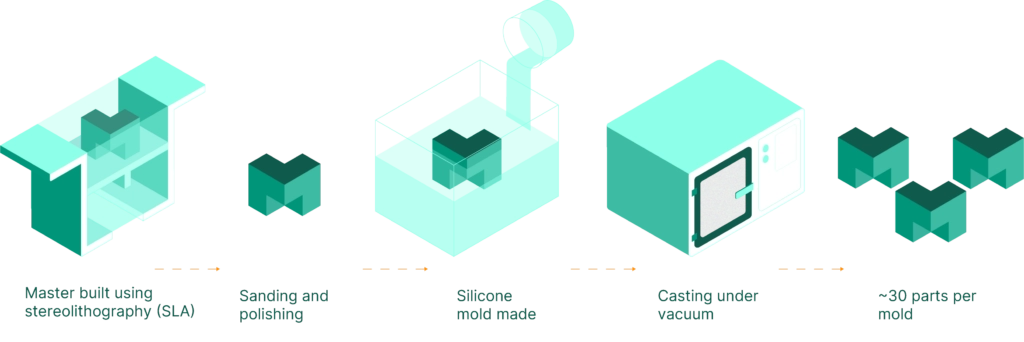

Vacuum casting starts with creating a master pattern, usually made from 3D-printed parts or CNC-machined models. This master serves as the basis for making silicone molds. The silicone mold is carefully prepared to capture all the details of the master pattern.

Next, polyurethane resin is mixed and poured into the silicone mold inside a vacuum chamber. This vacuum environment helps draw the resin deep into the mold, ensuring precision and reducing air pockets. Vacuum degassing is a key step here, removing any trapped air bubbles from the resin to prevent defects in the final part.

Once the resin is poured, the mold is left to cool and solidify. After the cooling phase, the part is carefully demolded to avoid damage. The final stage involves quality checks and finishing touches like trimming excess material, sanding, or painting, making sure the product meets required standards before delivery.

Advantages of Using a Vacuum Casting Factory

Choosing a vacuum casting factory comes with clear benefits, especially for prototype and low-volume manufacturing needs. Here’s what makes vacuum casting stand out:

- High Precision and Superior Surface FinishVacuum casting delivers detailed parts with smooth surfaces, closely matching the quality of injection molded products. This means less post-production work and better-looking prototypes or final parts.

- Fast Turnaround TimeBecause vacuum casting uses silicone molds and streamlined processes, it’s perfect when you need parts quickly. Whether it’s rapid vacuum casting for prototypes or small batches, you get reliable results without long wait times.

- Cost-Effective Alternative to Injection MoldingFor small runs, vacuum casting avoids the heavy upfront costs of injection molds. It’s budget-friendly without sacrificing quality, making it ideal for testing designs or limited production runs.

- Works with Diverse Materials and ColorsVacuum casting factories offer a wide range of polyurethane casting materials. You can pick from various colors and finishes to match your product’s look and feel exactly, enhancing design flexibility.

- Flexibility in Product Design and CustomizationSince silicone molds are easier to modify than metal tools, vacuum casting handles design changes and custom features quickly. This is a big advantage when you need to tweak parts or create unique prototypes.

Overall, vacuum casting factories provide a practical, efficient route to high-quality parts suited to the specific needs of U.S. businesses focused on innovation and speed.

Applications of Vacuum Casting

Vacuum casting is widely used across various industries thanks to its precision and versatility. Here are some common applications where vacuum casting shines:

- Automotive parts and componentsFrom durable interior trims to functional engine parts, vacuum casting helps create detailed prototypes and low-volume production parts that need strength and a high-quality finish.

- Consumer electronicsIt’s great for making detailed housings, buttons, and other small parts where appearance and fit matter, giving electronics a polished, professional look early in development.

- Medical device prototypesVacuum casting offers the accuracy and smooth finish required for testing medical devices, helping manufacturers refine designs before mass production.

- Aerospace and defensePrecision and material options make vacuum casting ideal for creating lightweight prototypes and parts that require strict quality control in aerospace and defense projects.

- Other industrial and creative usesThe flexibility in materials and colors makes vacuum casting perfect for creating functional prototypes, artistic models, and parts for industrial machinery or consumer goods.

Vacuum casting’s ability to produce high-detail parts quickly and affordably makes it a go-to solution for many prototypes and limited runs across these fields.

How to Choose the Right Vacuum Casting Factory

Picking the right vacuum casting factory can make all the difference for your project’s success. Here are key factors to keep in mind:

Factors to Consider

| cURL Too many subrequests. | What to Look For |

|---|---|

| Expertise | Years in vacuum casting, industry experience |

| Technology | Up-to-date equipment, use of silicone mold vacuum casting |

| Capacity | Ability to handle your order size and deadlines |

| cURL Too many subrequests. | Quality standards like ISO, RoHS compliance |

Communication and Custom Solutions

Clear communication is essential. Look for a partner willing to understand your specific needs and offer tailored solutions, whether it’s prototype vacuum casting or low volume manufacturing.

Turnaround Time and Quality Control

Fast vacuum casting production lead time matters, especially for prototypes. Make sure the factory has strong quality control to ensure consistency across batches.

Geographic Considerations

Decide if you want a local or international provider. Local factories offer easier communication and quicker shipping, while international ones might offer cost advantages.

Why Choose Vast

Vast stands out with its modern facilities, quick turnaround, and customized vacuum casting services for the U.S. market. With extensive experience and solid client testimonials, Vast combines quality and speed — making it a reliable partner for your vacuum casting needs.

Common Challenges and Solutions in Vacuum Casting

Vacuum casting is a powerful method, but like any process, it comes with its own set of challenges. Understanding these issues helps you work smarter with your vacuum casting factory partner.

Material Limitations

Some polyurethane casting materials may not meet every strength or flexibility need. The solution? Choosing the right vacuum casting material options or blending materials to get the best performance without losing detail or finish.

Shrinkage and Structural Integrity

Shrinkage is common during cooling and can affect part dimensions and strength. To combat this, precise mold design and fine-tuned process controls are key. Factories often adjust cure times and temperatures to minimize shrinkage while keeping parts sturdy.

Maintaining Uniform Quality Across Batches

Batch-to-batch consistency matters, especially in low volume manufacturing. Vacuums casting factories use strict quality control checks and standardized procedures to ensure every piece meets the same high standard without surprises.

Overcoming Design Complexity

Intricate designs and undercuts can be tricky with vacuum casting. Silicone mold vacuum casting helps by offering flexibility in mold shapes, allowing complex parts to be produced without compromising on detail.

Working with an experienced vacuum casting factory that understands these challenges ensures smooth production and high-quality results every time.

The Role of Innovation and Technology in Vacuum Casting Factories

Vacuum casting factories are evolving fast, thanks to new tech and innovative approaches that boost quality and efficiency. Advanced vacuum casting equipment now offers better control over pressure and temperature, which means fewer defects and more consistent parts.

Automation is also changing the game. Digital monitoring systems keep a close eye on every step of the casting process, catching issues early and ensuring precision without slowing production down. This technology helps factories deliver fast turnaround times with less waste.

Sustainability is another key focus. Many vacuum casting factories are switching to eco-friendly materials like bio-based polyurethanes and using energy-efficient machines. These efforts reduce the environmental footprint while still meeting tight quality standards.

In short, innovation in vacuum casting combines smarter machines, real-time tracking, and green materials to offer better, faster, and cleaner manufacturing solutions for today’s prototype and low-volume production needs.

Cost Factors and Pricing Models in Vacuum Casting Services

When considering vacuum casting services, it’s helpful to understand the main cost drivers:

- Tooling: Creating silicone molds is the biggest upfront expense. The more complex and detailed the part, the higher the tooling cost.

- Materials: Polyurethane resins vary in price depending on properties like flexibility, strength, or color. Choosing the right material will impact the total cost.

- Labor: Skilled technicians handle mold making, casting, finishing, and quality checks. Labor costs include time for setup, production, and post-processing.

Compared to other prototyping methods like injection molding, vacuum casting is generally more affordable for low-volume manufacturing. You avoid the high tooling fees of metal molds and get faster turnaround, making it ideal for prototypes and small batch runs.

Tips for Budgeting Vacuum Casting Projects

- Plan your batch size carefully: More units usually decrease cost per part.

- Choose materials wisely: Balancing performance with price helps control expenses.

- Focus on design simplicity: Complex shapes can increase tooling and labor.

- Get detailed quotes: Make sure the supplier includes all costs like finishing and shipping.

- Consider turnaround time: Faster services often cost more, so align speed with your project needs.

Understanding these factors helps you get the best value from a vacuum casting factory and stay within budget.

How Vast Excels as Your Vacuum Casting Factory Partner

At Vast, we’ve built our vacuum casting factory with top-notch facilities designed to deliver high-quality parts quickly and efficiently. Our equipment supports rapid vacuum casting and silicone mold vacuum casting, ensuring precision and consistency for every project. We specialize in prototype vacuum casting and low volume manufacturing, making us a go-to partner for industries needing fast, reliable results.

What sets Vast apart is our commitment to quality, speed, and customization. We work closely with clients to tailor solutions that fit their specific needs, whether it’s casting polyurethane parts in different colors or accommodating complex designs. Our skilled team pays attention to every detail—from mold setup to finishing touches—to guarantee outstanding surface finishes and dimensional accuracy.

We’ve helped businesses across automotive, medical, and consumer electronics sectors bring their ideas to life. Our case studies highlight projects completed on tight deadlines without compromising quality. If you’re looking for a vacuum casting factory partner that combines experience with client-focused service, Vast is ready to deliver.

Getting started is simple: reach out to us for a detailed quote and project consultation. We’re here to answer your questions and streamline your vacuum casting production lead time.

FAQs about Vacuum Casting Factories

How long does vacuum casting take?

Vacuum casting typically takes between 7 to 14 days from mold creation to finished parts, depending on project size and complexity. Rapid vacuum casting services can sometimes deliver faster for urgent prototypes.

What materials can be used in vacuum casting?

Most vacuum casting factories use polyurethane resins, which offer a variety of options in strength, flexibility, and color. Some factories also work with silicone-based and other specialty resins to meet specific needs.

Can vacuum casting replicate injection molding quality?

While vacuum casting delivers high precision and excellent surface finish close to injection molding, it’s best suited for prototypes and low-volume runs, not large-scale production. The parts are very similar but may lack some of the durability of injection-molded parts.

What is the minimum order quantity?

Most vacuum casting factories accept small batches, often starting as low as 5 to 10 parts. This makes vacuum casting a great choice for prototyping and limited production runs.

How do I request a quote from Vast?

Requesting a quote from Vast is easy: just provide your design files and project details through their website or contact team. Vast offers personalized support to help with material selection, lead time, and pricing tailored to your exact needs.