Explore advanced automated assembly machines boosting precision efficiency and scalability in manufacturing with cutting-edge industrial automation solutions.

What is an Automated Assembly Machine

An automated assembly machine is specialized equipment designed to perform repetitive assembly tasks with minimal human intervention. Its core function is to streamline production by assembling components quickly, accurately, and consistently.

Core Functionality

- Automates repetitive tasks: Joins parts, inserts fasteners, or performs welding and testing.

- Maintains product consistency: Reduces errors found in manual assembly.

- Increases production speed: Operates continuously without fatigue.

Key Components and Operation Principles

| Component | Role |

|---|---|

| Actuators | Move parts and tools to assemble components |

| Sensors | Monitor positioning and quality control |

| Controllers | Coordinate machine tasks and timing |

| Feeding systems | Supply components automatically |

| Human-Machine Interface (HMI) | Allows operators to monitor and control processes |

These components work together using precise programming and control logic, ensuring each assembly step is executed correctly.

Automated vs Manual Assembly

Automated assembly machines outperform manual assembly in:

- Speed: Machines can operate 24/7 at a consistent pace.

- Accuracy: Sensors and precise controls minimize errors.

- Labor costs: Reduces need for manual labor and training.

- Safety: Limits worker exposure to repetitive or hazardous tasks.

In contrast, manual assembly relies heavily on human dexterity and attention, making it less efficient, more prone to inconsistencies, and more costly for high-volume production.

Automated assembly machines transform industrial assembly automation by optimizing workflow and ensuring quality, forming the backbone of modern manufacturing processes.

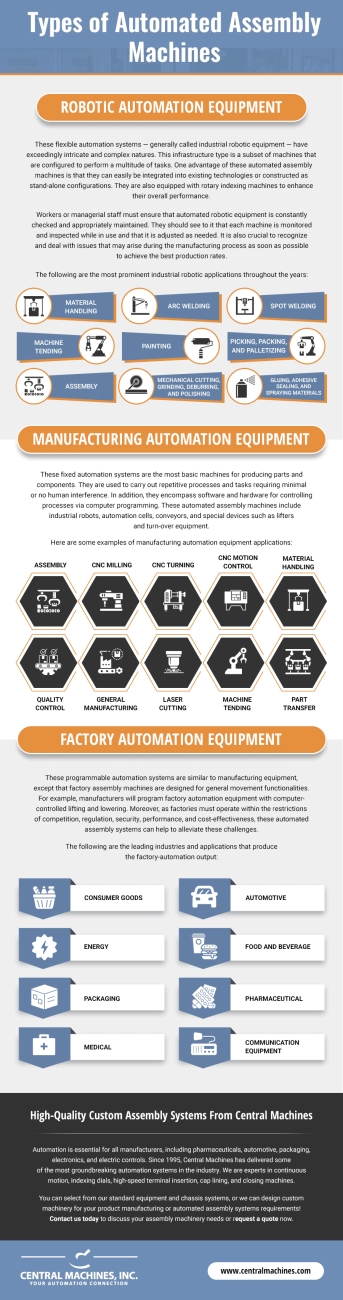

Types of Automated Assembly Machines

When looking at automated assembly machines, there are several common types used in U.S. industries, each designed to fit different production needs.

Pneumatic Assembly Machines

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

| cURL Too many subrequests. | cURL Too many subrequests. |

|---|---|

| Speed and Throughput | Higher output with consistent timing |

| Precision and Quality | Less defects, uniform product assembly |

| Labor and Error Reduction | Lower costs, fewer mistakes |

| Scalability and Flexibility | Quick adjustments to production needs |

| Workplace Safety | Decreased injury risks and safer jobs |

Common Applications and Industries

Automated assembly machines are at the heart of many industries across the United States, helping to boost productivity and consistency. Here are the main sectors where these machines really shine:

- Electronics ManufacturingPrecise and efficient assembly is crucial in electronics. Automated assembly lines handle delicate components like circuit boards, connectors, and microchips faster than manual processes, ensuring fewer errors and higher quality.

- Automotive AssemblyIn auto manufacturing, robotic assembly machines are widely used for tasks such as fastening parts, welding, and installing components. Automation speeds up production while maintaining tight quality standards demanded by the industry.

- Consumer Goods ProductionFrom packaging household products to assembling small appliances, automated production machines enable fast, consistent output. This helps companies keep up with consumer demand and reduce labor costs.

- Medical Device AssemblyPrecision assembly systems are essential here since accuracy and cleanliness directly affect safety. Automated systems ensure consistent production of items like surgical instruments, diagnostic devices, and implants with minimal contamination risk.

- Aerospace and DefenseAssembly automation technology supports the production of complex aerospace parts with stringent quality and safety needs. It helps handle intricate assemblies efficiently while complying with regulatory standards.

These industries rely heavily on industrial assembly automation to improve quality, reduce errors, and speed up manufacturing—all crucial for staying competitive in the U.S. market. If you’re looking to optimize your production setup, choosing the right automated assembly machine tailored to your industry is key.

How to Choose the Right Automated Assembly Machine for Your Business

Choosing the right automated assembly machine is crucial for maximizing efficiency and return on investment. Here’s what to keep in mind:

Assess Production Volume and Complexity

- Volume: Know your daily or monthly output needs to pick a machine fast enough to keep up.

- Complexity: More intricate products may require advanced precision assembly systems or robotic assembly machines.

Evaluate Integration Compatibility

- Check if the new machine can easily connect with your current automated manufacturing equipment or existing assembly automation technology.

- Look for standard communication protocols and easy software compatibility.

Consider Flexibility and Future Scalability

- Choose a machine that can adapt to different product types or sizes.

- Make sure it supports upgrades or modular add-ons for future production changes.

Support and Maintenance Services

- Reliable service availability nearby is a must.

- Consider training programs for your operators.

- Look for straightforward maintenance with accessible troubleshooting guides.

Budget and ROI Considerations

| cURL Too many subrequests. | cURL Too many subrequests. |

|---|---|

| Initial Cost | Assembly machine price and installation fees |

| Operating Costs | Energy usage, parts replacement, labor savings |

| ROI Timeline | How quickly efficiency gains offset costs |

| Long-term Value | Durability and upgradability |

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

- cURL Too many subrequests. cURL Too many subrequests.

- cURL Too many subrequests. cURL Too many subrequests.

- cURL Too many subrequests. cURL Too many subrequests.

cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

cURL Too many subrequests.

- cURL Too many subrequests.

- Keep essential spare parts on hand for quick replacements.

- Use remote monitoring tools when possible to catch issues before they cause shutdowns.

Following these best practices helps you get the most from your automated assembly line, improving reliability and boosting productivity.

The Future of Automated Assembly Machines

The future of automated assembly machines is shaped by exciting trends that are transforming industrial assembly automation across the U.S. One major development is the integration of AI and IoT technologies. These smart systems allow machines to monitor their own performance, predict maintenance needs, and optimize production flow in real time. This means less downtime and greater overall efficiency.

Collaborative robots, or cobots, are also gaining traction. Unlike traditional robotic assembly machines that work in isolation, cobots safely collaborate with human operators on the assembly line. This blend of automation and human skill boosts precision without sacrificing flexibility.

Sustainability is another key focus. Newer automated production machines are designed to consume less energy and reduce waste, aligning with growing environmental standards and helping businesses cut operational costs.

Looking ahead, companies like VAST are driving next-generation assembly automation by emphasizing modular, adaptable systems. These machines are built for easy upgrades, letting manufacturers scale and customize their assembly lines as their needs evolve.

In short, automated assembly machines are becoming smarter, more user-friendly, and eco-conscious—ready to keep U.S. manufacturing competitive and efficient well into the future.