Discover how to identify and prevent sand fusion in casting with expert tips on causes, materials, and process controls for defect-free sand castings.

Understanding Sand Fusion in Casting What It Is and Why It Matters

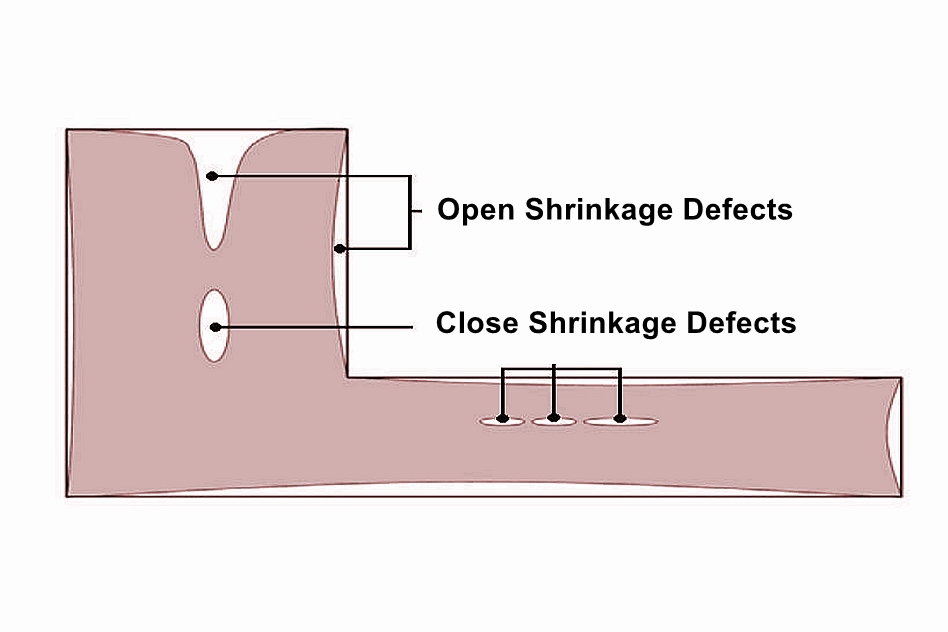

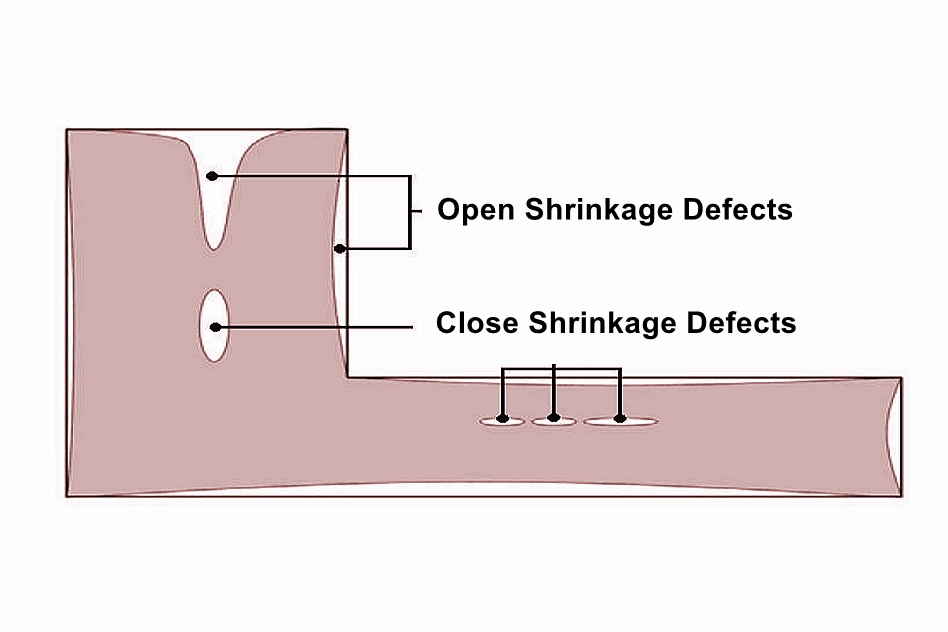

Sand fusion in casting is a defect that occurs when sand grains from the mold fuse or bond with the molten metal during the casting process. This fusion results in rough surfaces, metal penetration, and surface irregularities that compromise both the appearance and mechanical integrity of the casting. At its core, sand fusion happens because the molten metal partially melts or chemically interacts with the sand grains, causing them to stick instead of separating cleanly.

Mechanically, sand fusion forms when the refractory properties of the molding sand are insufficient to withstand the high temperatures of the molten metal. As a result, sand particles break down and fuse onto the metal surface, creating brittle crusts or hard spots. Unlike similar defects such as sand burn or metal penetration—which involve sand particles being embedded loosely—sand fusion specifically denotes a hard bond between metal and sand.

It’s important to differentiate sand fusion from related defects:

- Sand burn: Occurs when gases cause localized sand discoloration but no hard bonding.

- Metal penetration: Molten metal flows into sand voids, but the sand does not fuse chemically.

- Scabbing: Sand cracks and flakes off the casting but remains loose.

Sand fusion stands out due to this durable fusion affecting casting quality.

In the U.S. foundry industry, sand fusion defects are a significant source of rework and scrap. Studies show that sand-related casting defects, including fusion, account for up to 20% of total casting defects, impacting both productivity and costs. Addressing sand fusion can reduce production delays and save thousands in scrap costs annually, making it a key focus for quality control and process optimization in sand casting operations nationwide.

Root Causes of Sand Fusion Defects in Sand Casting

Sand fusion happens when the molding sand can’t stand up to the heat of molten metal, causing sand grains to stick or fuse to the casting surface. One major culprit is low refractoriness of the molding sand. If the sand’s heat resistance is too low, it breaks down or melts under high temperatures, leading to metal penetrating the sand and creating surface defects.

Another big factor is excessive pouring temperatures. When metal is poured hotter than it should be, it increases the chances of sand grains melting or sticking to the casting. Controlling pouring temperature is crucial to keep sand fusion in check.

Inadequate binders or additives also weaken the sand’s heat resistance. Poor-quality binders fail to hold sand grains together firmly at high temperatures, allowing them to break down and fuse with the metal.

Some secondary factors contribute as well:

- Coarse sand grains that create uneven surfaces may trap molten metal more easily.

- Mold design flaws, such as poor venting or insufficient cooling, worsen thermal stresses, making sand fusion more likely.

Case Study: Optimizing Sand to Cut Down Fusion Defects

A midwestern foundry faced frequent sand fusion issues that slowed production and increased scrap rates. After switching to a higher refractoriness sand mix and improving binder formulations, they saw a 40% reduction in fusion defects. Adjusting pouring temperature and refining mold design with better venting further helped minimize fusion spots on cast parts.

This example shows how a combined approach—choosing better materials and refining process controls—can significantly improve sand casting quality by preventing sand fusion.

How to Identify Sand Fusion in Your Castings

Spotting sand fusion early in your sand casting process saves time and reduces costs. Here’s what to look for and how to confirm the defect.

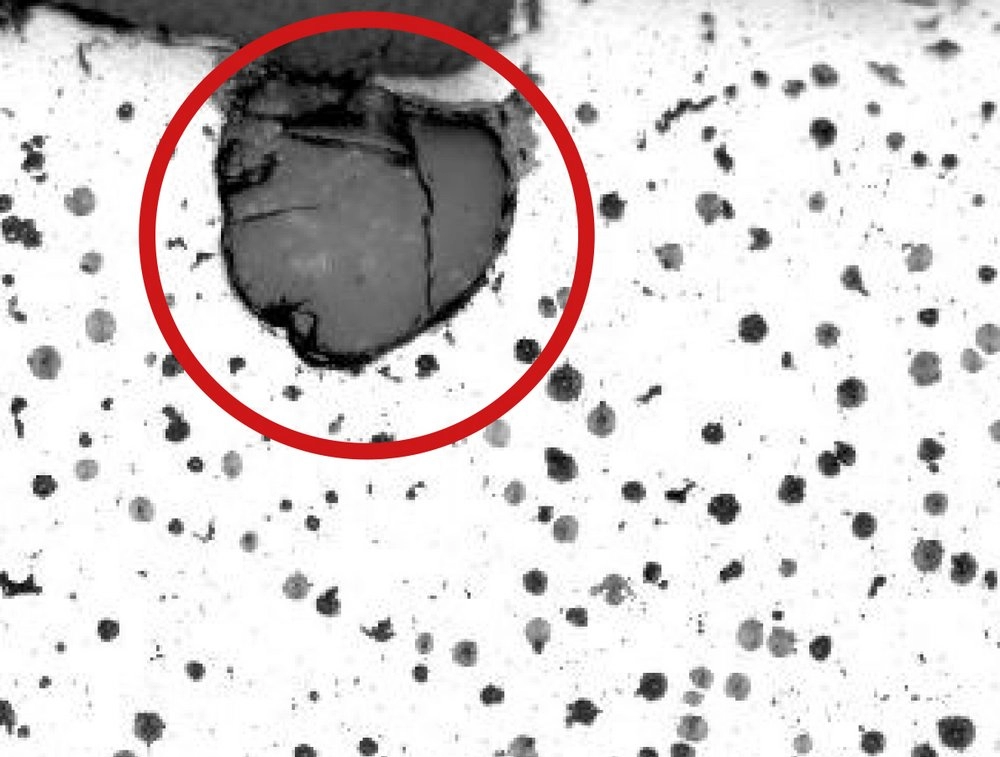

Visual Signs and Common Locations

- Surface roughness or brittle crusts where the metal and sand have bonded.

- Metal penetration marks that look like small pits or fused grains embedded in the casting surface.

- Areas near sharp corners, gates, and risers tend to show sand fusion more due to higher thermal stresses.

- Blistering or sand grains welded onto the casting surface cURL Too many subrequests.

cURL Too many subrequests.

- cURL Too many subrequests. cURL Too many subrequests.

- cURL Too many subrequests. cURL Too many subrequests.

- cURL Too many subrequests. cURL Too many subrequests.

- cURL Too many subrequests. cURL Too many subrequests.

cURL Too many subrequests.

| cURL Too many subrequests. | cURL Too many subrequests. | cURL Too many subrequests. |

|---|---|---|

| cURL Too many subrequests. | cURL Too many subrequests. | cURL Too many subrequests. |

| cURL Too many subrequests. | cURL Too many subrequests. | Lower pouring temperature / control ladle |

| Pits or metal penetration | Coarse or poorly bonded sand | Improve sand grading and binder mix |

| Defects near gating/riser | Poor mold design or venting | Redesign mold / improve venting |

Using these methods helps keep sand fusion under control, ensuring better casting quality without costly rework.

Proven Strategies to Prevent Sand Fusion in Casting Processes

Preventing sand fusion in casting starts with using the right materials and controls. Here’s how I recommend tackling it:

Choose High Refractory Sands

Pick sands with a high melting point and good heat resistance, like zircon, chromite, or olivine. These sands handle molten metal better and reduce fusion risks compared to regular silica sand.

Enhance Binders for Stability

Use quality binders that can withstand high temperatures without breaking down. Improving thermal stability helps keep the sand mold intact during pouring, preventing the sand grains from fusing with the metal.

Control Pouring Temperatures

Keep the pouring temperature in check. Pouring metal that’s too hot increases the chance of sand fusion. Regular ladle temperature monitoring ensures the metal stays within safe limits.

Apply Refractory Mold Washes and Coatings

A coat or wash of refractory material on the mold surface creates a protective barrier, stopping sand grains from sticking to molten metal. It also smooths the surface, limiting defects.

Improve Mold Design for Venting and Cooling

Good mold design is key. Proper venting lets gases escape, reducing pressures that push sand grains into the metal. Better cooling controls the metal’s solidification, lowering fusion chances.

Use Advanced Techniques

Tech tools add an edge:

- 3D sand printing offers precise control over mold density and design.

- Simulation software helps predict problem spots and optimize pouring conditions before casting.

Step-by-Step Prevention Protocol

- Test sand refractory properties regularly

- Choose binders matched to your casting specs

- Monitor pouring temperature closely

- Apply refractory coatings consistently

- Design molds with venting in mind

- Use simulation tools for process planning

- Train operators on defect prevention

Following these steps keeps your casting process solid and reduces costly sand fusion defects effectively.

Real-World Fixes and Case Studies Overcoming Sand Fusion at Vast

At Vast, we’ve tackled sand fusion head-on with a mix of mechanical and chemical post-casting remedies to improve casting quality. Here’s a quick look at what worked and what didn’t:

cURL Too many subrequests.

- cURL Too many subrequests. cURL Too many subrequests.

- cURL Too many subrequests. cURL Too many subrequests.

cURL Too many subrequests.

- cURL Too many subrequests. cURL Too many subrequests.

- cURL Too many subrequests. cURL Too many subrequests.

cURL Too many subrequests. cURL Too many subrequests. cURL Too many subrequests.

cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests. cURL Too many subrequests. cURL Too many subrequests.

- cURL Too many subrequests.

- Train operators on defect recognition and immediate action protocols.

These steps don’t just cut down sand fusion; they also improve overall casting efficiency and reduce waste, crucial for any US-based foundry competing on quality and cost.

Best Practices for Defect-Free Sand Casting Beyond Fusion

To keep your sand casting free from defects like sand fusion and others, a few proven practices really make a difference.

Routine Sand Testing and Operator Training

Regularly testing your molding sand helps spot issues like low refractoriness or contamination before they cause problems. Pair this with good operator training focused on recognizing early signs of defects and proper handling techniques. Well-trained staff and clean, tested sand are your first line of defense.

Integrating AI and Hybrid Processes

Using AI-driven monitoring systems can catch anomalies in pouring temperature, sand moisture, and other key factors in real-time. Hybrid processes that combine traditional casting with advanced controls reduce human error and ensure consistent quality.

Top 5 Low-Cost Changes to Reduce Sand Fusion Risks

- Switch to higher refractoriness sand varieties like zircon or chromite where possible.

- Optimize pouring temperature, keeping it just high enough to fill the mold without overheating.

- Use mold coatings or washes to add a protective barrier between metal and sand.

- Adjust binder mixes to improve heat resistance without adding cost.

- Improve mold venting and cooling to avoid hot spots that promote sand grain fusion.

Sticking to these best practices helps you cut down sand fusion defects and keeps your casting process running smooth and efficient.