Discover expert fastening solutions for construction manufacturing and aerospace with custom options durable corrosion-resistant and vibration-proof.

If you’re responsible for selecting fastening solutions in manufacturing, construction, or any high-stakes industry, you know that a weak connection can bring an entire project to a halt. Choosing the right fastening solutions isn’t just about joining parts—it’s about ensuring durability, safety, and efficiency under the toughest conditions. In this guide, you’ll discover how to navigate the complex world of industrial fasteners, from screws and rivets to cutting-edge hybrid methods, and learn practical tips to secure your assemblies with confidence. Ready to optimize your fastening strategy and avoid costly failures? Let’s dive in.

What Are Fastening Solutions and Why Do They Matter

Fastening solutions are the methods and products used to join two or more materials together securely. They include a wide range of industrial fasteners such as bolts, screws, rivet nuts, washers, and anchors. These solutions are crucial because they provide stability, strength, and durability to assemblies in various industries.

Why do fastening solutions matter? Without reliable fasteners, structures and products can fail, leading to costly repairs, safety risks, and downtime. For example, in construction, corrosion-proof anchors ensure buildings remain safe over time. In automotive manufacturing, precision nutrunner tools help assemble vehicles quickly while maintaining top quality.

Choosing the right fastening solution means considering factors like the materials involved, environmental conditions, and the type of load the fastener must handle. This ensures that the joint will withstand vibration, stress, and wear, which is vital in demanding fields like aerospace or marine applications.

In short, fastening solutions are the hidden heroes behind everything from bridges to smartphones. They keep parts connected, safe, and functioning as intended. Understanding these fundamentals sets the stage for finding the perfect fastening method tailored to your unique needs.

Key Components of Effective Fastening Systems

When it comes to fastening solutions, having the right components makes all the difference. Effective fastening systems are built from several key parts that work together to provide strength, durability, and reliability.

- Fasteners: These are the basic elements like bolts, screws, rivets, and nuts. Choosing the right type depends on your project’s load requirements and environment.

- Washers: Vibration-resistant washers help prevent loosening in high-motion applications. They also distribute pressure evenly to protect materials.

- Anchors: Corrosion-proof anchors are essential for securing fastening systems in harsh environments like outdoor construction or marine settings.

- Tools: Precision nutrunner tools and proper installation equipment ensure fasteners are tightened correctly, improving safety and longevity.

- Materials: Using exotic alloy screws or corrosion-resistant metals keeps joints strong over time, especially in demanding conditions.

- Design: Structural joining methods and engineered assembly techniques matter. A well-planned fastening system avoids stress points and promotes even load distribution.

Each component plays a specific role in the system, and when combined properly, they offer a fastening solution tailored to your application’s needs. Whether you’re managing inventory fasteners for a manufacturing line or looking for custom bolt suppliers, understanding these parts is the first step to success.

Types of Fastening Solutions A Comprehensive Breakdown

Mechanical Fasteners The Workhorses of Assembly

Mechanical fasteners are the most common fastening solutions you’ll find in everyday projects and industrial settings. They include bolts, screws, nuts, rivets, washers, and anchors—basically the reliable parts that hold pieces together firmly. These fasteners are favored for their strength, ease of installation, and ability to disassemble when needed.

Some key points about mechanical fasteners:

- Versatility: Used everywhere from construction sites to automotive assembly lines.

- Strong Holding Power: Ideal for structural joining methods where durability is critical.

- Wide Range of Options: You’ll find industrial fasteners like exotic alloy screws, vibration-resistant washers, and corrosion-proof anchors tailored for different environments.

- Installation Tools: Tools such as precision nutrunner tools and rivet nut installation kits help ensure fasteners are applied correctly for maximum performance.

- Reusability: Unlike adhesives, mechanical fasteners can often be removed and reused, making maintenance and repairs easier.

Mechanical fasteners remain the backbone of assembly across many industries because they blend reliability with cost-effective performance, especially in settings where safety and strength can’t be compromised.

Engineered and Specialty Solutions for Demanding Applications

When standard mechanical fasteners don’t cut it, engineered and specialty fastening solutions step in. These options are designed for tough conditions where strength, precision, and durability are non-negotiable. Think of custom bolt suppliers who tailor fasteners to fit unique dimensions or exotic alloy screws built to resist extreme heat and corrosion.

Some common engineered solutions include:

- Threaded Inserts and Rivet Nut Installation: Perfect for thin materials where strong, durable threads are critical.

- Vibration-Resistant Washers and Locking Fasteners: Keep assemblies secure even under constant motion or heavy vibration.

- Corrosion-Proof Anchors: Ideal for outdoor or marine environments where rust resistance is a must.

These specialty fasteners require precision installation tools like nutrunner tools to ensure everything fits perfectly and lasts. By using engineered assembly techniques, you get fastening solutions that can handle extreme loads, harsh chemicals, or constantly changing stresses.

In industries like aerospace, automotive, and heavy machinery here in the U.S., these solutions can be the difference between long-lasting performance and costly failures. Whether you’re managing inventory fasteners for high-volume production or working on structural joining methods, specialty fasteners provide reliable, tailored results for demanding projects.

Adhesive and Hybrid Alternatives When Traditional Won’t Cut It

Sometimes, mechanical fasteners like bolts and rivets just don’t fit the bill. That’s where adhesive and hybrid fastening solutions come in. These options are perfect when you need a clean look, want to avoid drilling holes, or deal with materials that might crack or deform under stress.

Adhesive Fastening uses special glues and resins to bond materials securely. These are ideal for lightweight parts or where vibration resistance matters, such as in electronics or composite structures. Plus, adhesive joints can distribute stress evenly and help prevent corrosion between different metals.

Hybrid Fastening Solutions combine adhesives with mechanical fasteners, giving you the best of both worlds — strong holding power plus added durability against vibration and shock. For example, a bonded bolt assembly relies on both the adhesive layer and the mechanical grip to provide maximum strength and reliability.

These alternatives work great in industries like aerospace, automotive, and even construction, where precision and longevity matter. When choosing these solutions, look for corrosion-proof anchors and engineered assembly techniques to ensure lasting performance.

If you need advice on choosing between mechanical, adhesive, or hybrid fastening systems, I can help guide you through managed inventory fasteners and custom bolt suppliers to find the right fit for your project.

Applications Across Industries Tailored Fastening for Real-World Success

Construction and Infrastructure Building with Reliability

In construction and infrastructure, fastening solutions play a huge role in making sure structures stand strong and safe. From bridges to commercial buildings, reliable industrial fasteners like corrosion-proof anchors and vibration-resistant washers help handle heavy loads and harsh weather. These components are essential for long-term durability and safety.

Common fastening needs here include:

- Structural joining methods that keep steel, concrete, and wood firmly connected

- Rivet nut installation for quick, strong assembly in tight spaces

- Use of exotic alloy screws to resist rust and wear in outdoor environments

These tailored solutions make sure projects meet strict safety codes while staying cost-effective. For local contractors and builders across the U.S., picking the right combination of fasteners can save time during installation and reduce future maintenance headaches.

By focusing on dependable fastening solutions, construction teams build infrastructure that lasts, even when exposed to the toughest conditions.

Manufacturing and Automotive Precision in High-Volume Production

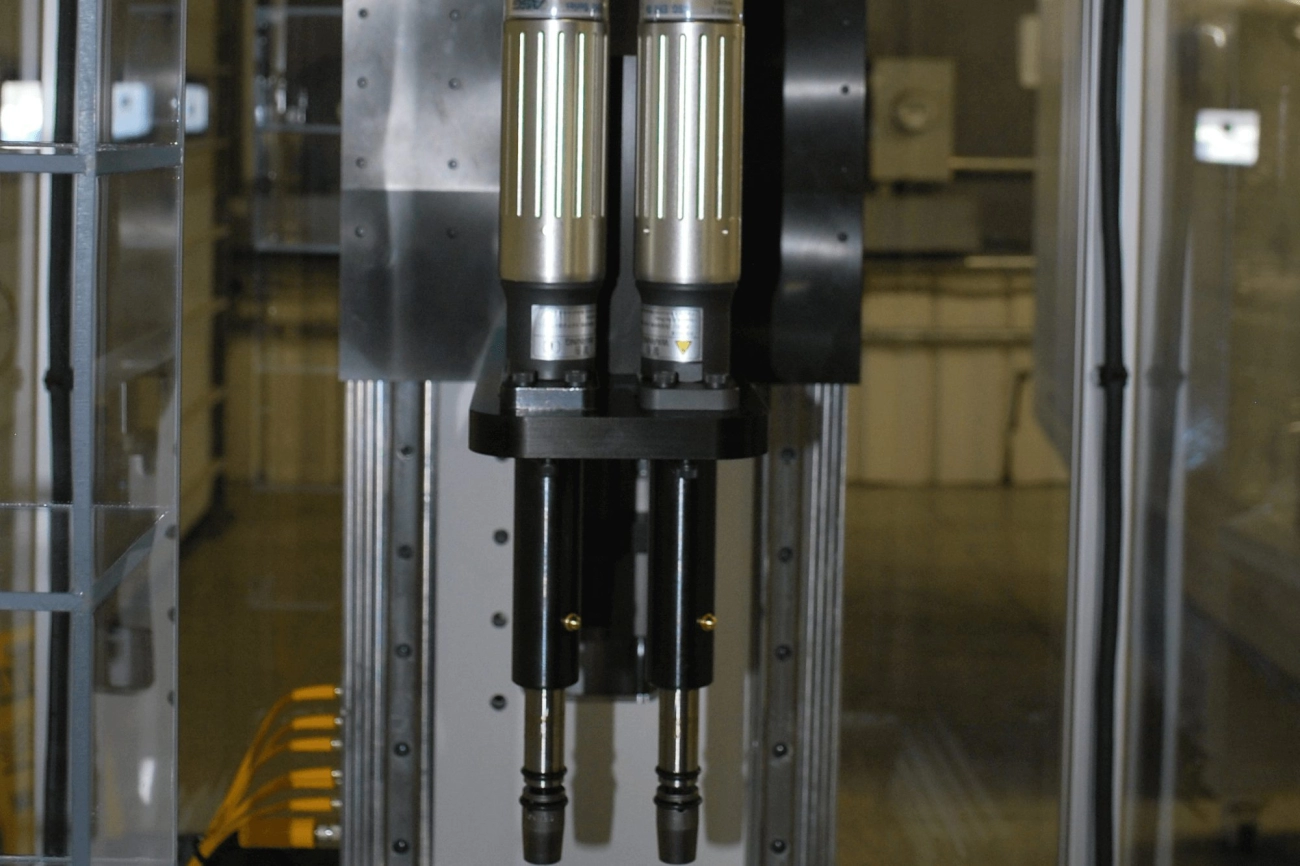

When it comes to manufacturing and automotive industries, fastening solutions need to deliver speed, accuracy, and durability—all at scale. High-volume production lines rely heavily on industrial fasteners like rivet nuts, exotic alloy screws, and vibration-resistant washers to keep things moving smoothly. Precision nutrunner tools and engineered assembly techniques help maintain consistent torque and reliable joins every time.

These industries demand fastening systems that can withstand constant vibration, heat, and stress without failing. Corrosion-proof anchors and custom bolt suppliers play a big role in meeting these tough standards. Managed inventory fasteners ensure production lines never slow down due to missing parts.

In short, fastening solutions in manufacturing and automotive jobs are all about balancing efficiency with long-lasting performance—keeping vehicles safe and production costs under control.

Aerospace Marine and Beyond Extreme Conditions Demystified

In industries like aerospace and marine, fastening solutions face some of the toughest challenges. Extreme temperatures, constant vibration, saltwater exposure, and high-pressure environments demand fasteners that won’t fail when it matters most.

That’s why aerospace and marine applications rely heavily on exotic alloy screws, corrosion-proof anchors, and vibration-resistant washers. These specialized fasteners are designed to withstand harsh conditions while maintaining structural integrity and safety.

For example:

- Aerospace assemblies often require precision nutrunner tools to ensure exact torque settings, avoiding loosening in flight.

- Marine structures use structural joining methods tailored to resist rust and salt damage over time.

These industries also benefit from engineered assembly techniques combining mechanical fasteners with adhesives or hybrid solutions to boost durability and performance.

Whether you’re securing aircraft components or building offshore platforms, choosing the right fastening solution that meets rigorous standards is key for lasting success in extreme environments.

How to Select the Right Fastening Solution Step-by-Step Selection Process

Choosing the right fastening solution can make all the difference in your project’s success. Here’s a straightforward way to pick the best option without guesswork:

1. Define Your Requirements

- Identify the materials you’re joining (metal, plastic, wood, etc.)

- Consider load strength, vibration, and environmental conditions (like corrosion or temperature)

- Know if the fastening will be permanent or removable

2. Choose the Fastener Type

- Mechanical fasteners like bolts, rivets, or nuts are great for strong, reusable joints

- Adhesives and hybrid options work well when you need a clean look or damage-free assembly

- Specialty fasteners like exotic alloy screws or corrosion-proof anchors suit extreme conditions

3. Check Size and Specifications

- Match thread size, length, and diameter to your specific needs

- Use precision nutrunner tools and vibration-resistant washers where needed for tight tolerances

4. Consider Installation Methods

- Decide if you need manual or automated installation (rivet nut installation, for example)

- Look for solutions compatible with your assembly line and tools

5. Evaluate Supplier Support

- Choose custom bolt suppliers or managed inventory fasteners with good delivery and technical help

6. Test and Validate

- Run small trials to check fit, strength, and durability before full-scale use

Following these steps will help you avoid costly mistakes and find fastening solutions that fit your project perfectly.

Common Mistakes and How to Avoid Them

Choosing the right fastening solutions can get tricky if you’re not careful. Here are some common mistakes I see—and how to dodge them:

- Ignoring the Application RequirementsUsing generic industrial fasteners instead of ones designed for your specific needs, like corrosion-proof anchors for outdoor use, can cause failures. Always consider the environment and load requirements.

- Overlooking Material CompatibilityMixing metals without checking for corrosion or weakness leads to premature wear. For example, don’t pair exotic alloy screws with incompatible materials—this can cause galling or rust.

- Skipping Proper Installation ToolsNot using precision nutrunner tools or skipping rivet nut installation best practices means joints aren’t secure. Proper tools make all the difference in achieving vibration-resistant fastening.

- Neglecting Vibration and MovementNot accounting for vibration in automotive or manufacturing settings often leads to fastener loosening. Using vibration-resistant washers and engineered assembly techniques helps keep everything tight.

- Choosing Cost Over QualityCheap fasteners might save money upfront but can increase downtime and repairs. Investing in managed inventory fasteners from custom bolt suppliers ensures consistency and reliability.

To avoid these pitfalls, take time upfront to evaluate your specific needs, select materials wisely, and follow installation best practices. This way, your fastening solutions will deliver long-lasting performance tailored to your project.

Installation and Maintenance Best Practices for Long-Lasting Performance

Proven Installation Techniques

Getting your fastening solutions installed right the first time saves time, money, and headaches down the road. Here are proven techniques we recommend for reliable, long-lasting performance:

- Prepare the surfaces well: Clean and remove rust, dirt, or oil before installing industrial fasteners. This ensures a solid, corrosion-proof anchor.

- Use the right tools: Precision nutrunner tools and torque wrenches help maintain correct tightening levels, preventing over- or under-tightening that can weaken structural joining methods.

- Follow manufacturer specs: Every engineered assembly technique requires specific torque settings, bolt grades, and sequences. Stick to these for best results.

- Choose vibration-resistant washers or locking fasteners: In environments with a lot of movement or vibration, these keep your assembly secure and prevent loosening.

- Apply proper rivet nut installation methods: Use powered tools or manual kits designed for consistent grip and accuracy, crucial for lightweight or thin materials.

- Avoid reuse of single-use fasteners: Certain bolts or rivets are designed for one-time installation. Reusing can compromise strength.

By following these steps, you ensure your fastening solution holds strong under stress and harsh conditions — making your projects safer and longer-lasting.

Ongoing Maintenance and Troubleshooting

Keeping your fastening solutions working well means regular checkups and quick fixes when problems pop up. Here’s what I suggest for ongoing maintenance and troubleshooting:

- Inspect regularly: Look for signs of wear, corrosion, or loosening on bolts, screws, rivet nuts, and other fasteners. Early detection helps avoid bigger issues.

- Tighten as needed: Use precision nutrunner tools to ensure fasteners stay at the right torque. Over time, vibration-resistant washers can loosen, so double-check them.

- Replace damaged parts: Corrosion-proof anchors or exotic alloy screws might fail in harsh environments. Swap out any fasteners that show signs of damage immediately.

- Clean fasteners: Dirt and debris can affect performance. Clean fasteners and surrounding areas regularly to maintain structural integrity.

- Monitor performance: In tough industries like aerospace or construction, track how fastening solutions hold up. This helps catch problems before they cause failure.

- Troubleshoot common issues:

- Loose connections: Re-tighten using recommended torque specs.

- Corrosion: Replace rusted fasteners with corrosion-proof alternatives.

- Fatigue cracks: Switch to engineered assembly techniques or specialty fasteners designed for heavy-duty use.

By following these simple steps, you ensure your fastening solutions stay reliable and strong, saving time and money down the road.

Partnering with Vast Your Source for Premium Fastening Solutions

Why Choose Vast

When it comes to fastening solutions, Vast stands out as a trusted partner for businesses across the United States. Here’s why working with us makes a difference:

- Wide Range of Industrial FastenersFrom custom bolt suppliers to exotic alloy screws and corrosion-proof anchors, Vast offers a full lineup of products to meet any assembly need.

- Expertise You Can Rely OnOur team understands engineered assembly techniques and structural joining methods, delivering solutions tailored to your project requirements.

- Quality and ConsistencyWe ensure every component, including vibration-resistant washers and rivet nut installation products, meets rigorous standards for durability and performance.

- Managed Inventory FastenersSave time and reduce downtime with our managed inventory options, designed to keep your production line running smoothly.

- Precision Tools and SupportVast provides access to precision nutrunner tools and offers expert guidance on installation and maintenance best practices.

Choosing Vast means you get more than just fasteners — you get a reliable partner that helps you streamline your projects and boost efficiency. We’re committed to delivering fastening solutions that work as hard as you do.

Partnering with Vast Your Source for Premium Fastening Solutions

Success Stories and Next Steps

At Vast, we’re proud to be a trusted partner for businesses across the U.S. who need reliable fastening solutions. From industrial fasteners for heavy machinery to precision nutrunner tools for high-volume manufacturing, our customers count on us to deliver quality and consistency every time.

Here are a few ways Vast has made a difference:

- Custom bolt suppliers for automotive plants reduced downtime by supplying high-strength exotic alloy screws tailored to specific needs.

- A construction firm improved structural joining methods by switching to our corrosion-proof anchors and vibration-resistant washers, which boosted safety and durability.

- Aerospace manufacturers relied on our engineered assembly techniques for consistent, reliable fastening in extreme conditions.

If you’re ready to get the best fastening solutions for your projects, here’s what to do next:

- Reach out to our local experts to discuss your application and challenges.

- Take advantage of our managed inventory fasteners to streamline your supply chain.

- Let us help you choose the right product, whether it’s rivet nut installation or a hybrid solution for tougher jobs.

Partner with Vast and experience the difference premium fastening solutions make in your business.